Understand the CVD Furnace: A critical device in material science

In the realm of advanced fabric technology and semiconductor manufacturing, the CVD furnace, or chemical vapor deposition furnace, holds a

pivotal position. As industries increasingly demand materials with superior properties, the flexibility and effectiveness of a CVD furnace come to

be more pronounced. In this post, we will delve into the intricacies of this technological surprise, exploring its capability, importance, and programs.

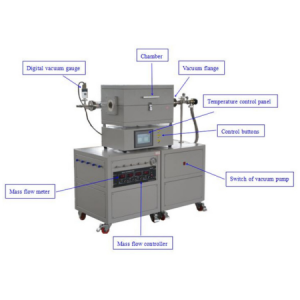

What is a CVD Furnace?

A CVD furnace is a complicated piece of device used for the deposition of thin films onto numerous substrates via a chemical vapor deposition

process. This approach includes the conversion of gaseous precursors into stable material thru chemical reactions. The CVD technique is renowned for its ability to produce uniform and high quality coatings, making it crucial in the fabrication of semiconductors, solar cells,and other advanced materials.

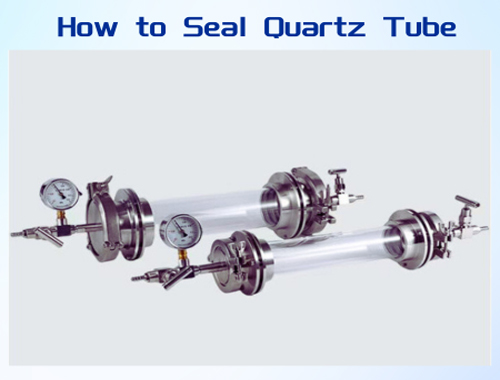

One common subtype of the CVD furnace is the CVD tube furnace. This configuration typically includes a cylindrical tube that homes the

substrate, making an allowance for evenly distributed warmth and gas go with the flow, which is important for attaining most reliable

deposition fees and film best. The layout of the tube mitigates contamination and ensures specific manipulate over the deposition

surroundings.

The operating principle of Chemical Vapor Deposition Furnaces

The operation of a chemical vapor deposition furnace entails 7 critical steps:

1. Precursor creation: Gaseous precursor materials are brought into the furnace chamber, frequently in a managed surroundings to

limit contamination.

2. Heating: The tube furnace is heated to increased temperatures, which facilitates the chemical reactionsvital for movie formation. The

thermal surroundings promotes the decomposition of precursors, leading to the deposition of stable cloth onto the substrate.

3.Thin FilmFormation: as the precursors react, they form a solid layer at the substrate floor, growing a thin film which can have particular electric,

optical, and structural homes.

4. Cooling and Purging: After the preferred film thickness is completed, the furnace undergoes a cooling and purging process to take away any

unreacted gases and prevent in addition deposition.

Application of CVD Furnaces:

The flexibility of CVD furnaces permits them to be applied throughout a selection of industries, consisting of:

- Semiconductor production: vital for the production of included circuits and photovoltaic properties, CVD strategies play a fundamental role in

depositing materials like silicon and graphene.

- Optical Coatings: CVD furnaces are used to create thin films with precise optical properties, enhancing the performance of lenses and mirrors

in diverse packages.

- Wear-Resistant Coatings: Industries make use of CVD tactics to deposit long lasting coatings on gear and additives, extending their lifespan

and enhancing overall performance.

Conclusion

In summary, the CVD furnace, especially the CVD tube furnace, is an imperative device in material technological know-how and engineering.

Its capability to supply thin films thru the chemical vapor deposition method makes it an important asset in diverse excessive-tech industries.

As generation progresses, the revolutionary skills of CVD furnaces will preserve to shape the destiny of material development, paving the way

for brand new programs and more suitable cloth overall performance.

Understanding the importance and capability of a CVD furnace permits professionals and lovers in the area to realize its effect on modern technology.

Whether or not you are new to the concern or a pro expert, the CVD furnace remains a cornerstone of advanced material synthesis well worth exploring further.